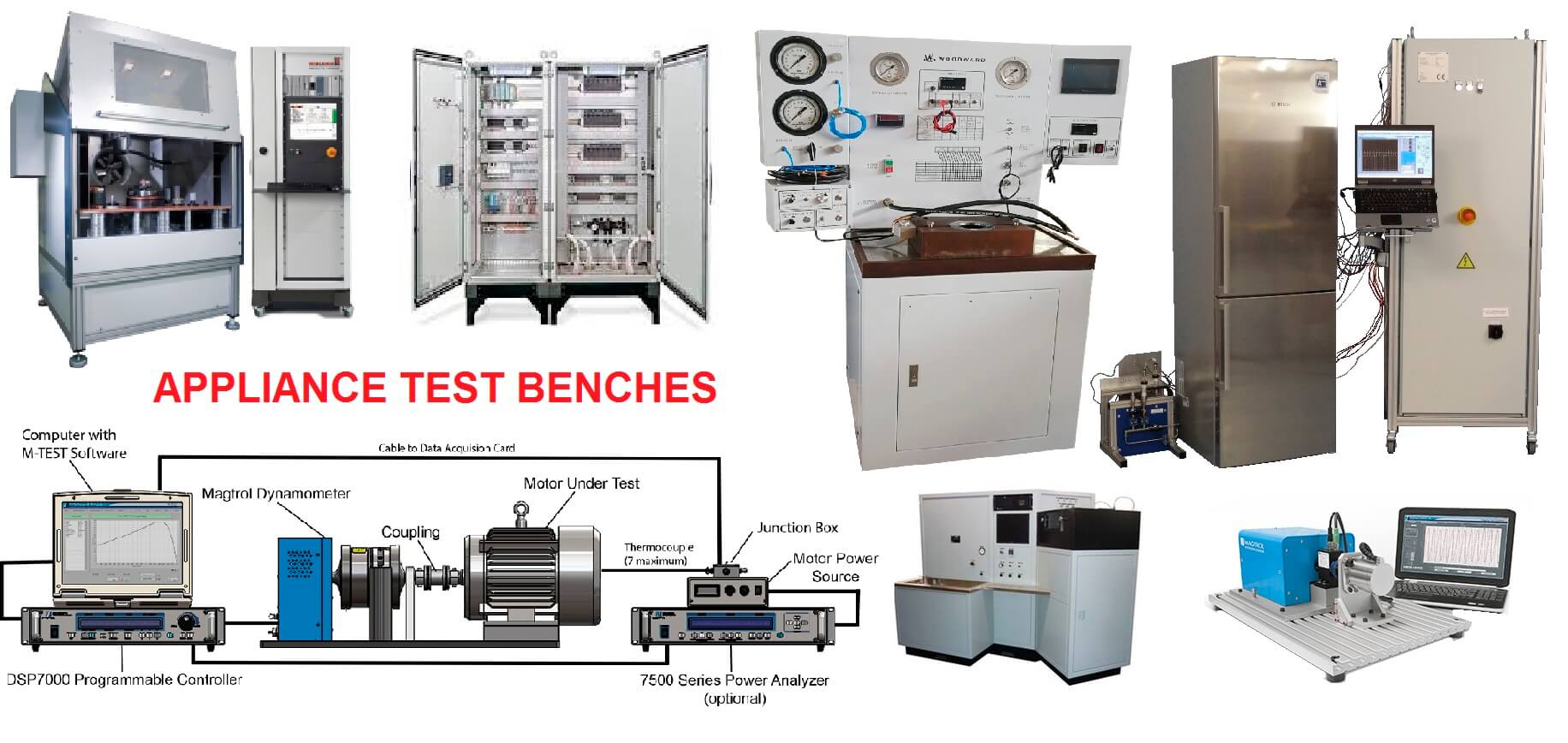

Ruvik Automation Pvt Ltd (RAPL) is a manufacturer of Home appliance Test Benches and test facilities, tailor made, for companies all over the world.

Of course, before an actual test facility of test rig will be manufactured detailed discussions concerning the specifications are inevitable. In addition, training services of the local engineers how to work with the specific equipment is an essential part of the total delivery..

Our systems offer real-time control and advanced data logging with high levels of customization to generate reports, both digital and paper, that are tailored specifically to the needs of the customer and product being tested.

A vacuum chamber is a rigid enclosure from which air and other gases are removed by a vacuum pump resulting in a low pressure environment within the chamber. The chambers allow the simulation of extreme programs in accordance with the relevant standards.

The test chambers are supplied with fully programmable control systems for the programming of all chamber functions. By the use of a range of controllers we are able to customize the chamber to meet your exact requirements. The chambers can also be supplied in a range of sizes and shapes to unable use to supplier our customers a full range of options to meet their specification requirements.

Test parameters are monitored through a dedicated PC and software packages developed for particular type of application.

The Air Compressor test bench comprises of a Single stage air compressor fitted with an air tank with orifice, pressure gauges, and an energy meter to measure the input & a Temperature indicator measures the temperatures at various points. The compressor is mounted on air receiver along with the motor, and is provided with air relief valve (safety) and a pressure switch. The unit determines volumetric efficiency and isothermal efficiency at various discharge pressures.

| TEST PARAMETERS: | |

|---|---|

| 1. Atmospheric pressure in mm. of Hg. 2. Discharge pressure of compressor in Kg/cm² 3. Stable absolute vacuum for exhauster in mm of Hg. 4. Speed of expresser in RPM. 5. Pressure at out let of LP/inlet of inter collar - Kg/cm² 6. Inter cooler pressure in Kg/cm² 7. Crank vacuum in mm of Hg. 8. Lube oil temp ºc 9. Lube oil pressure in Kg/cm² 10. Atmospheric temperature in - ºc 11. Air temperature at inlet to LP- ºc 12. Air temperature at outlet from LP- ºc 13. Exhauster in take air temperature - ºc 14. Air temperature at inlet to HP- ºc 15. Air temperature at outlet for HP- ºc |

16. Exhauster discharge temp in - ºc 17. LP delivery Cap Temp - ºc 18. HP delivery Cap temp - ºc 19. Exhauster delivery cap temp - ºc 20. Crank case body temp - ºc 21. LP cylinder head temp - ºc mode. 22. HP cylinder head temp - ºc 23. Exhauster cylinder head temp. 24. Voltage in volts. 25. Current in amp. 26. Power in kilowatt. 27. Bearing end temp - ºc 28. Lube oil consumption in lit.min. 29. Water Flow Rate. 30. Water tube temperature |

The Bump test is also a useful vibration analysis technique to identify resonance frequencies in a machine's structure. It requires bumping or hitting the machine structure when the machine is in “OFF” condition. This allows you to measure its natural frequencies. It tests the integrity & rigidity of the object under the simulation of Road Transport condition.

This computerized machine is a versatile test equipment to carry out bump tests in accordance with various IS, MIL-810F, DIN, EN, ISO, IEC, DEF and ASTM standards.

TYPES:

• Free Fall Type

• Force Impact Type

TESTS:

• Traditional Bump Test

• Bump Test using Long Time Waveform

• Commtest Bump Test

• Long Time Waveforms Explained

• Measuring Long Time Waveforms

SYSTEM PARAMETERS:

• Acceleration - 3 g to 60 g

• Pulse duration - 3 ms to 18 ms

• Payload capacity - 1 kg to 1000 kg

• Number of bumps - unlimited

• Bump rate - 60 to 180 bumps per minute.

The Battery charger tester is to measures the energy efficiency of battery chargers coupled with their batteries. The term "battery charger tester" covers all rechargeable batteries and the chargers used with them. All types of rechargeable batteries are charged and tested, including nickel cadmium, nickel metal hydride, lead acid, and lithium ion.

We provide custom designed testing solution to meet our customer’s wide ranging applications as per the requirements.

FEATURES:

• Can Handle Both Rechargeable and Primary Battery Applications

• Extremely Flexible and Reliable

CHARGER EVALUATION PARAMETERS:

• AC input voltage

• AC input current

• Battery voltage

• DC current

• Ground current.

Simulation Transportation Vibration Tester which simulates a transporation environment, is applicable to the vibration test of toys, electronics, furnitures, gifts, ceramics, communications, packagings, equipment, computer and automobile components, etc.

Specifications:

Max. Test Load 100 Kg

Frequency Range 60-300 rpm

Amplitude Range 25.4 mm (1 inch)

Vibration Mode Roundtrip

Simulation Speed 25~40 km/h

Woke Table Size 1000×1200 mm

Outside Dimension (L×W×H) 1255×1070×660 mm

Power Capacity 1 HP

Weight 125 Kg

Environmental Conditions Temperature: 5~40°c; Related Humidity: 85%

Speed Mode DC converter or AC Frequency Control

Standard: IS7028 EN71 ANSI,UL,ASTM ISTA .

Air Conditioner Test Bench is capable of testing the Cooling Capacity & Performance of AC.

The Test Set-up consists of:-

• Temperature DAQ Card

• Electrical Power Input Card

• Sensors for Temperature, Barometric Pressure, Flow

• DAQ Software including PC

Test Chamber:

• Capacity : Single unit test at a time

• Temp & RH control

• Temp: Ambient to 65°C

• RH:0 to 80%

The Refrigeration & Air Conditioning Test Setup provides facility for testing in the area of commercial refrigeration and air conditioning. It is used extensively in performance testing and computer modelling of various refrigeration and air conditioning unitary systems, energy rating of various types of air conditioners.

The facility was recently expanded with the addition of another temperature controlled test room built to comply with AS 1731 and ISO 23953. The test room is capable of testing commercial refrigeration units (both self-contained and remote condensing), refrigerated vending machines and heat pump hot water systems.

Test Standards –

• Non Ducted Units – AS/NZS3823.1.1

• Ducted Units – AS/NZS3823.1.2

• Water Source Heat Pumps – AS/NZS3823.1.3

• Assessment using Simulation Methods – AS/NZS3823.3

It should be noted that there are close links between the AS/NZS test standards and

ISO test standards, which reflects Australia and New Zealand aligning to world best practice. The ISO standards include:

• ISO5151 (non ducted)

• ISO13253 (ducted)

• ISO13256-1 (water source).

Air Cooler Test Rig unit is required to conduct experiments and demonstrate the basic principal of psychometric properties of air. The test rig is designed for study of cooling of air. The unit is provided with all instruments and facilities to measure the temperature wherever required. The setup provides the facility to conduct the experiment of cooling of air by temperature measurements.

experrimentation/learing objectivies

• To study the operation of cooling of air.

• To calculate the change in specific humidity of air utilities required

• Electric supply: Single Phase, 220 V AC, 50 Hz., 32 Amp. MCB with earth connection. Earth voltage should be less than 5 volts.

• Water Supply: Initial fill.

• Floor Drain Required.

• Floor Area : 4.5 m x 1.5

Tecnical Details:

• Blower : For Air flow, compatible capacity

• Water Tank : Material Stainless Steel, Compatible capacity • Water Circulation : By pump, 0.5 HP

• Water Flow Measurement : By Rotameter, compatible capacity

• Sling Psychometer : For dry bulb and wet bulb temperature measurement.

• An ENGLISH instruction manual consisting of experimental procedures, block diagram etc. will be provided along with the Apparatus.

• The whole set-up is well designed and arranged on a rigid structure painted with industrial PU Paint .

The test rig is designed for the study of thermodynamics of vapour Compression refrigeration cycle by way of demonstration and experimentation. It has a facility to measure various parameters for experimentation.

FEATURES:

• The Vapour Compression refrigerator cycle.

• Calculate Co-efficient of performance utilities required

• Electric supply: Single phase, 220 V AC, 50 Hz, 5-15 amp combined socket with earth connection. Earth voltage should be less than 5 volts.

• Water supply: 2LPM@1bar

• Floor drain required.

• Floor area: 1.5 m x 1.

Techanical Detail:

• Compressor : Hermitically sealed compressor, Reciprocating type. Capacity 1/3 Ton, Emerson Copeland make.

• Refrigerant : R-134-A

• Agitator : Compatible capacity.

• Condenser : Air cooled compatible to compressor

• Condenser Cooling Fan : Compatible capacity with permanent lubricated motor.

• Evaporator : Made of Stainless Steel, Insulated with ceramic wool/P.U.F.• Rotameter : Make: Eureka, Range (6-60) LPH

• Expansion Device : Capillary Tube, Compatible Capacity.

• Pressure Gauges : 2 Nos. (For suction & discharge pressure)

• Safety Control : Overload and over current protectors for compressor and Time delay circuit with Low/high voltage auto-cut.

• Temperature Sensor : RTD PT-100 Type

• Control Panel comprises of : Digital Voltmeter : 0-500 V Digital Ammeter : 0-19.99Amp. Temperature Measurement : Digital Temperature Indicator with multi-channel switch. With mains indicator, Standard make On-off switch etc.

• All Other accessories like Hand shut off valves, filter drier and Thermostat (Danfoss make) will be provided.

• An ENGLISH instruction manual consisting of experimental procedures, block diagram etc. will be provided along with the Apparatus.

• The whole set-up is well designed and arranged on a rigid structure painted with industrial PU Paint.

The device uses the Seimens/Yokogawa PLC control, 7 inch color touch screen operation. Built in voltage regulator, can guarantee the rated voltage input. The equipment is composed of an electric control cabinet, a sample holder and two mechanical hand mounted on the sample holder (step motor drive).

The machine frame is made of high grade aluminum alloy profile, and the mechanical hand is respectively installed on the beam and the supporting column of the frame, can satisfy left open door and the upper door test to different sizes washing machine.

Control: advanced Seimens/Yokogawa PLC

• Display: true color liquid crystal display (7 Inch Touch screen)

• Frame structure: High grade aluminum profile

• Power supply: AC 220V 50HZ ( can be customed)

• Manipulator: Two, side manipulator and upper manipulator. Replaceable vacuum suction and gripping device.

• Auxiliary mechanism: 0-50mm stroke adjustable

• Floor adjustment mechanism: to adjust the sample level, tilt

• Test times: 0-999999 preset, automatic stop when test time finished• Open/Close time: 0-9999S preset• Open/Close rate Adjustable

• Open angle: Side manipulator 0-180°, upper manipulator -30-90°

• Station Two station(left open and upper open)

Standard:

IEC 60335-2-7 household and similar electrical appliances – safety: part 2-7:particular requirements for washing machines, clause 18.101and clause 22.104; IEC 60335-2-11 household and similar electrical appliances – safety: part 2-11:particular requirements for tumble dryers, clause 20.101.

This Performance Test Lab is used for measuring the performance of clothes washing machines for household use.

Feature:

1. The ambient temperature of the test room shall be maintained at (23 ± 2) °C throughout the washing machine test. The measured ambient temperature for washing machine testing shall be reported, it shall be rounded to the nearest 0.5 °C.

2. The static (gauge) pressure of the laboratory supply water at the inlet to each test washing machine shall be maintained at (240 ± 50) kPa throughout the test, including during filling operations.

3. The temperature of the laboratory supply water to each test washing machine shall be measured and recorded to the nearest 0,1 °C. It shall be:

– for cold water (1 5 ± 2) °C for all reference programmes except Cotton 20 °C

– for cold water (20 ± 2) °C is the recommended option when using the Cotton 20ºC reference programme. This is recommended for test washing machine programmes with no internal heating and cold fill only (cold water wash).

The cold water supply temperature to the reference machine in this case may be the same as the test washing machine or it may be 1 5 ºC as specified above.

– for hot water the temperature indicated by the manufacturer ± 2 K, or (60 ± 2) °C, if no value is given.

4. The supply voltage to each test washing machine shall be maintained at the rated voltage±2 % throughout the test. If a voltage range is indicated, then the supply voltage shall be the nominal voltage of the country in which the appliance is intended to be used.

5. The supply frequency to each test washing machine shall be maintained at the rated frequency ±1 % throughout the test. If a frequency range is indicated, the test frequency shall be the nominal frequency of the country in which the machine is intended to be used.

.